Fabric inspection is the process of examining fabric for defects and other problems. Common fabric defects include spots, stains, holes, tears, and wrinkles. Fabric inspection is typically done before the fabric is cut or processed further.

Packing is the process of preparing fabric for shipment. This usually involves folding the fabric and placing it in a box or on a pallet. Packing materials such as tissue paper or packing peanuts may be used to protect the fabric during shipping.

What is Involved in Fabric Inspection?

In order to ensure that fabrics are of the highest quality, they must undergo a rigorous inspection process. This usually begins with an evaluation of the fabric's physical properties, such as its weight, dimensions, and appearance. Once the fabric has been deemed acceptable, it is then put through a series of tests to check for defects. These tests can include assessments of the fabric's strength, colorfastness, and resistance to abrasion. After passing all inspections, the fabric is ready to be used in products or shipped to customers.

What Is Required for Packing Lines?

In order to ensure that textile products are of the highest quality, manufacturers must utilize a fabric inspection and packing line. This type of packing line allows for each individual fabric roll to be checked for defects before being packaged for shipment. By conducting a thorough inspection of each fabric, manufacturers can avoid sending out defective merchandise and ensure that their customers are satisfied with their purchase.

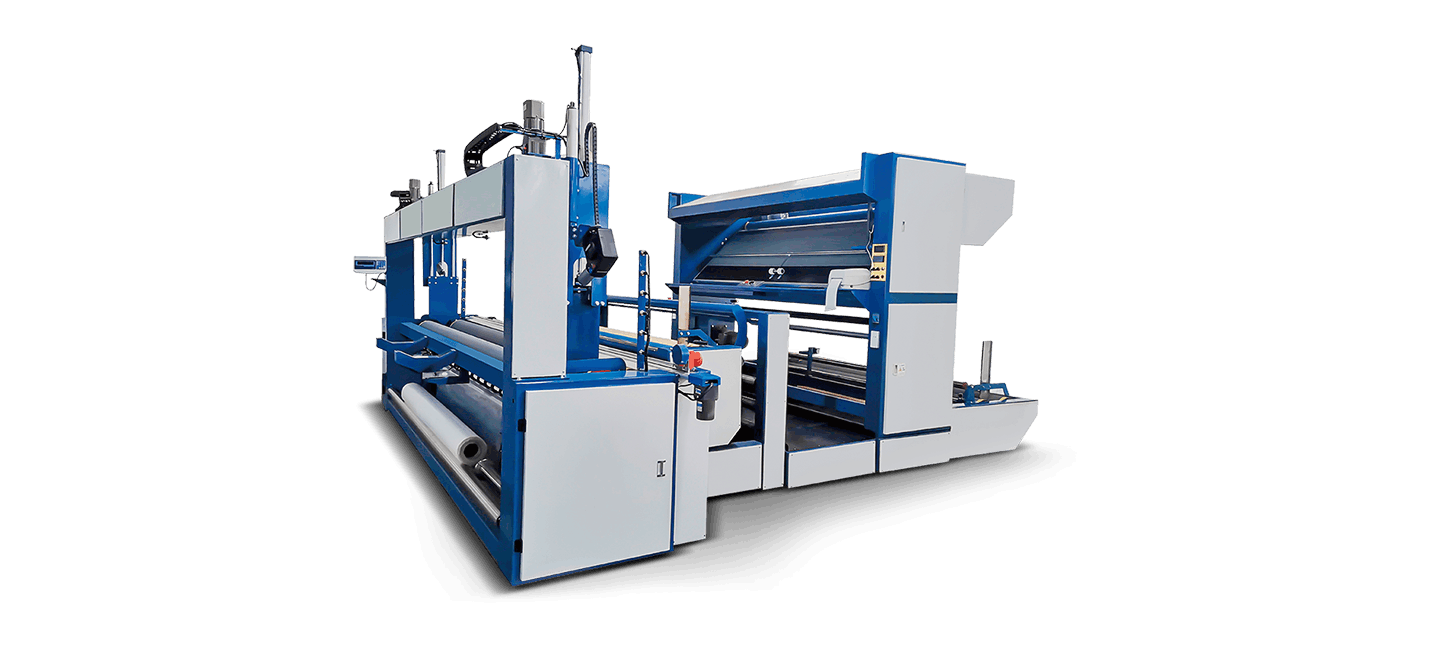

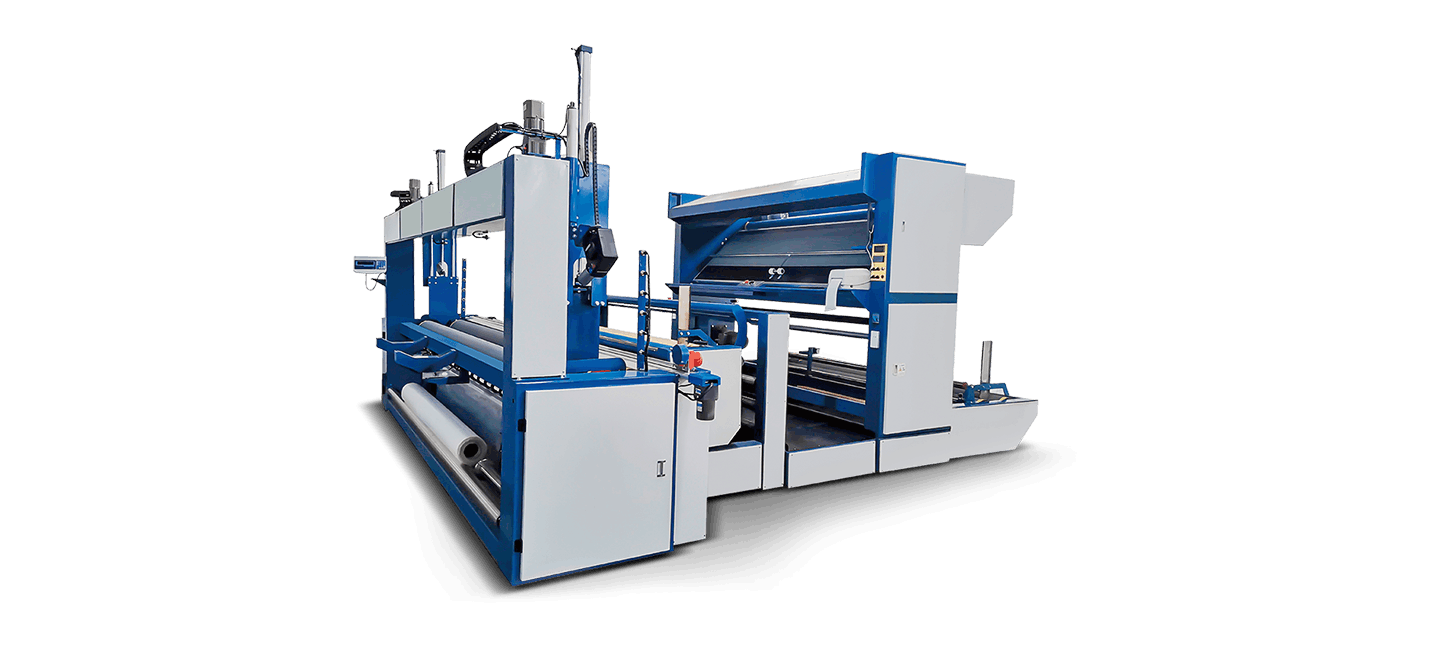

Packaging lines typically consist of several different types of machinery, including an inspection table, conveyor belt, and packing machine. The inspection table is where each product is placed so that it can be examined for any defects. Once the inspection is complete, the product is then placed on the conveyor belt which moves it to the packing machine. The fabric packing machine wraps and labels the product before it is finally ready to be shipped.

By utilizing a fabric inspection and packing line, manufacturers can rest assured knowing that their fabric products are of the highest quality before they leave the factory. This not only helps to improve customer satisfaction but also helps to protect the reputation of the company.

Benefits of Automation in Fabric Inspection and Packing Line

The textile industry is one of the most labor-intensive industries in the world. Automation in fabric inspection and packing can help reduce labor costs and improve efficiency.

When it comes to fabric inspection, automated systems can help improve accuracy and consistency. For example, an automatic optical inspection system can be used to inspect fabric for defects such as holes, stains, or tears. This can help to ensure that only high-quality fabrics are used in the manufacturing process.

Packing is another area where automation can be beneficial. Automated packing systems can help to minimize material waste and improve packing efficiency. For example, an automated system can be used to fold and pack fabric neatly into boxes or bags. This can help to save time and increase productivity.

Overall, automation can have a positive impact on the textile industry by reducing labor costs, improving accuracy and consistency, and increasing efficiency.

Importance of Quality Control in The Textile Industry

Quality control is important in any industry, but it is especially critical in the textile industry. This is because textile products are used in a wide variety of applications, from clothing to upholstery to industrial fabrics. If a textile product is defective, it can cause serious problems. For example, a piece of fabric that tears easily may not be suitable for clothing. A defective airbag may not deploy correctly in a car accident.

Textile products must meet strict safety and quality standards before they are sold. To ensure that these standards are met, manufacturers undergo regular quality control inspections. During these inspections, experts examine the fabrics and other materials used in the manufacturing process to look for defects. They also test the finished products to make sure they meet the required standards.

Quality control is essential to the textile industry because it helps to ensure that products are safe and fit for their purpose. Without quality control, there would be a greater risk of defective products being sold, which could cause serious injuries or even deaths.

Common Problems Faced During Fabric Inspection & Packing Line

The textile industry is a fast paced and ever-changing environment. There are many different types of fabric and each one has its own set of guidelines for inspection. The most common problems faced during fabric inspection and packing line are:

1. Inconsistent Quality - There can be a lot of variation in the quality of fabric from one batch to the next. This can make it difficult to maintain consistent standards during inspection.

2. Time Constraints - The Inspectors are under a lot of pressure to work quickly and efficiently. This can sometimes lead to rushed decisions and mistakes being made.

3.Language Barriers - There is often a language barrier between the workers on the packing line and the inspectors. This can make communication difficult and lead to misunderstanding.

4. Lack of Training - Inspectors may not have received proper training on how to inspect certain types of fabric or they may be unfamiliar with the latest technology being used in the packing line.

5 .Missing Pieces - It is not uncommon for pieces of fabric to go missing during the inspection process. This can delay production and cause frustration for all parties involved.

Tips for Prevention of Defects on Fabric Inspection and Packaging Lines

It is important to prevent defects on fabric inspection and packing lines in the textile industry. Some tips for doing so are listed below:

- Inspect all fabric before it is cut. This includes checking for any knots, nubs, or other imperfections.

- Cut fabric accurately. This means using a rotary cutter or shears instead of scissors whenever possible. It also means cutting straight lines and measuring twice before cutting.

- Fold fabric correctly. This means folding the selvage edges together first, then folding the length of the fabric in half. Once the fabric is folded in half, fold it again into quarters. Finally, fold the corners into the center to create a small triangle.

-Packaged fabrics should be free of wrinkles and creases. To achieve this, use tissue paper or bubble wrap to protect sharp folds and creases during packaging.

Conclusion

In conclusion, fabric inspection and packing lines are an essential part of the textile industry. They ensure that fabrics are up to standard and properly packaged for transport or storage. The fabrication quality control procedure is a tedious process but one that ensures accuracy and consistency in the product manufactured by the manufacturing plant. With advances in technology, more efficient inspection machines and automated packaging lines can be used to further enhance production efficiency.