As the textile industry faces increasing demands for speed, quality, and cost-effectiveness, efficient material handling solutions help meet these challenges by optimizing workflows, reducing labor costs, and ensuring consistent quality. With the right material handling equipment in place, weaving mills can achieve greater operational efficiency, reduce production costs, and maintain competitiveness in a fast-paced market.

As an experienced textile machinery supplier, SUNTECH brings you how the continuous upgrading of material handling equipment in the textile industry can improve efficiency.

Overview of Material Handling Equipment in the Textile Industry

Material handling equipment refers to the tools, machinery, and systems used to move, store, control, and protect materials and goods during manufacturing, warehousing, distribution, and disposal. In the textile industry, these systems are critical for the efficient movement and storage of materials like fabric rolls, beams, and finished goods, which are key components in textile production.

Common Types of Material Handling Equipment in the Textile Industry

1. Forklifts

Forklifts are widely used in the textile industry to transport heavy loads of raw materials, such as fabric rolls, or finished goods. They are versatile and can navigate narrow aisles and tight spaces within factories or warehouses.

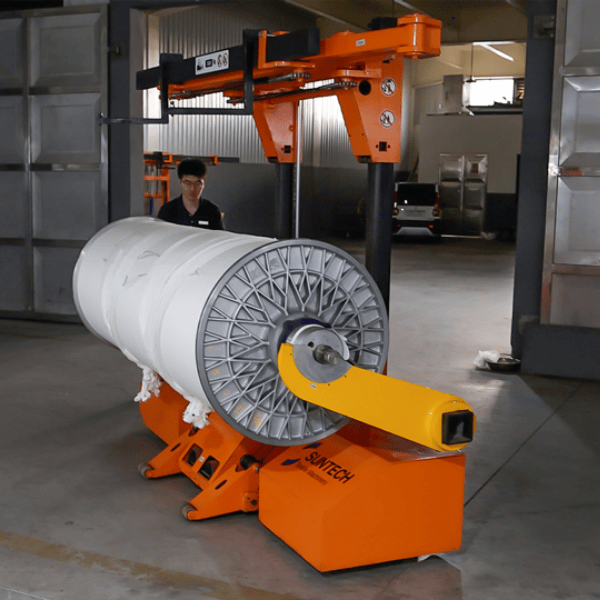

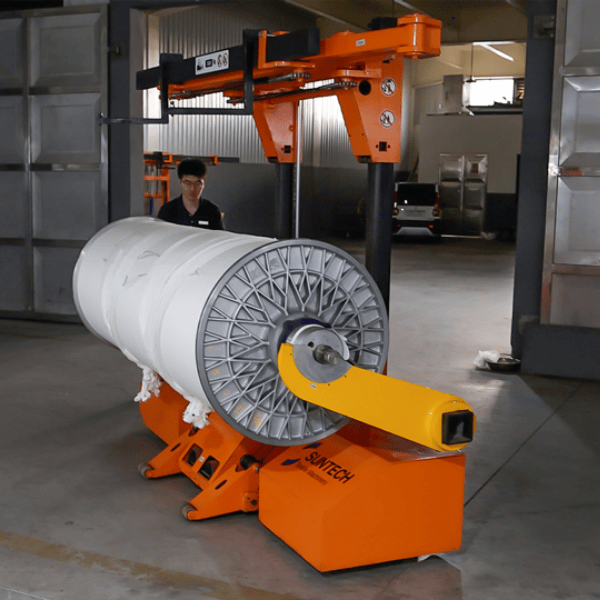

2. Warp Beam Trolley

These trolleys are specialized machines used for loading and unloading warp beams, warp knitting beams, and other types of textile beams onto looms. They facilitate the smooth transfer of beams between storage areas and weaving machines, reducing the need for manual labor and improving operational efficiency.

3. Transport Trolley

Transport trolleys are used to move loads of textiles, such as warp beams, or other components, throughout the factory. These trolleys can be manually or automatically operated, depending on the level of automation in the facility.

4. Beam Stackers

Beam stackersare used to store and organize warp beams, knitting beams, or fabric rolls. These stackers provide efficient storage solutions and help organize large quantities of material to streamline production processes.

Key Features of Textile Industry Handing Equipment

Adaptability: Textile materials vary significantly in weight, size, and handling requirements. Equipment must, therefore, be adaptable to handle diverse materials under various environmental conditions without compromising on performance.

High Load Capacity: Equipment such as motorized and hydraulic beam trolleys are critical for transporting heavy textile beams. These trolleys have a high load capacity, ensuring they can handle the weight of heavy materials, which is crucial for maintaining production efficiency.

Ease of Maneuverability: Despite their robust construction, this equipment needs to be maneuverable within the confines of textile factories, where space can be limited.

Role of Material Handling Equipment in Textile Production

Material handling equipment plays a vital role in increasing productivity, improving workflow, and ensuring the safe handling of materials throughout the textile production process. Here are some of the key functions:

1. Efficient Transportation: These machines help transport materials from one stage to another within the textile production process, whether it's from the warehouse to the production line or between different processing stages like dyeing, weaving, or finishing.

2. Time and Labor Savings: Automating material movement through equipment like electric warp beam trolleys and transport trolleys saves valuable time and reduces manual labor, making production more cost-effective.

3. Safety: Material handling equipment helps minimize the risk of injury to workers by reducing the need for manual lifting and moving of heavy or bulky materials.

4. Inventory Management: Equipment like beam stackers and automated transport systems improve the organization and accessibility of raw materials and finished products, helping to streamline inventory management.

![Warp Beam Trucks Warp Beam Trucks]()

Example

SUNTECH Motorized Warp Beam Trolley: This specific model is tailored for the textile industry, facilitating the movement of upper warp beams and aiding in tasks such as machine threading and storage management. The ST-MBT series is known for increasing productivity by up to 50% compared to manual handling. Features such as a gel battery provide long service life and extended operating times, crucial for continuous production environments.

Conclusion

By incorporating material handling equipment into textile production, companies can achieve higher levels of automation, reduce operational costs, improve safety, and enhance overall productivity. This ultimately leads to a more competitive, sustainable, and efficient textile manufacturing process.