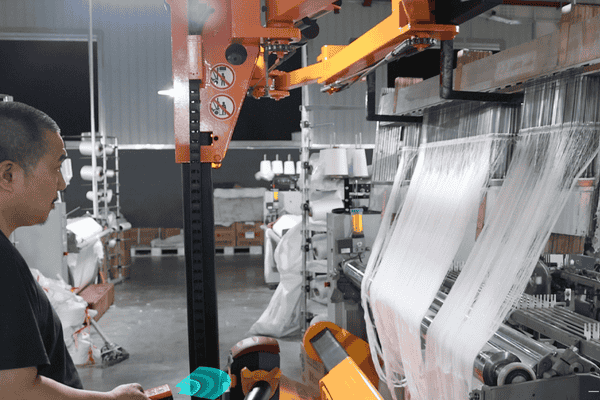

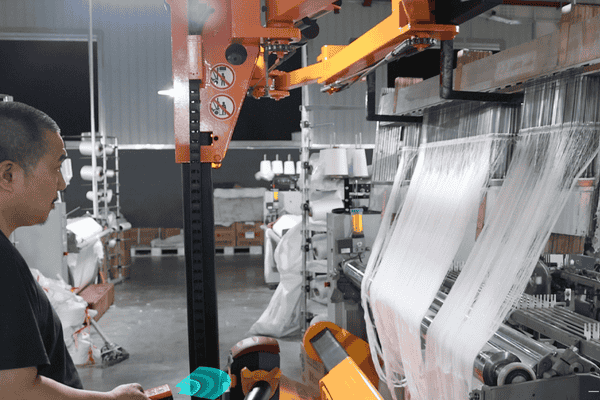

In modern textile workshops, the handling and installation of warp beams is a crucial link. Traditional manual handling methods are not only time-consuming and labor-intensive, but also have high safety risks. As an intelligent handling device designed specifically for the textile industry, the Electric warp beam trolley can effectively improve handling efficiency, ensure operational safety, and reduce labor costs. It has become the first choice of more and more textile companies.

So, how does the electric warp beam trolley ensure safe and efficient handling in textile workshops? SUNTECH will conduct an in-depth discussion on its working principle, core advantages, safety design, and key points for purchase.

Introduction

The electric warp-beam trolley is an intelligent device specially used for transporting and installing warp beams. It integrates an electric drive system, a lifting device and an intelligent control system, which can easily complete the movement, lifting and installation of warp beams, reducing the burden of manual operation. Compared with traditional methods, the electric warp-beam trolley has higher stability and safety, and is especially suitable for the warp beam processing needs of large-scale textile workshops.

Challenges of Textile Factories

In the traditional warp beam processing process, the workshop may encounter the following challenges:

High manual operation intensity: The warp beams are usually heavy (up to hundreds of kilograms), and manual handling can easily cause fatigue or even work injuries.

Equipment is easily damaged during handling: Since the warp beams are large and easy to roll, the equipment or the ground may be damaged if they are not handled with care.

Difficult alignment and installation: It requires extremely high operating skills to accurately align the warp beams with the loom and install them, otherwise it may affect production efficiency.

Many safety hazards: During the handling process, the warp beams may fall or collide with a slight carelessness, which poses a great safety hazard.

![3.31-1.2]()

Electric Warp-Beam Trolley Improves Efficiency

(1) Electric Drive System Improves Operation Efficiency

The electric warp-beam trolley is equipped with a stepless speed control drive system, which allows the operator to easily adjust the operating speed and achieve precise control. Whether it is going straight, turning or aligning the warp beam storage position, the equipment can run smoothly to avoid delays caused by improper operation.

(2) Hydraulic Lifting Device, Precise Height Adjustment

The electric hydraulic system allows the operator to adjust the height of the warp beam with one click to ensure that it can be accurately aligned with the loom or storage rack without repeatedly adjusting the position, thereby improving the warp beam loading efficiency.

(3) EPS Steering System, Easy Control of Heavy-Laded Warp Beams

High-end electric warp-beam trolleys are usually equipped with an electronic power steering system (EPS). Even if operated by a single person, they can easily carry warp beams weighing up to 3,000 kilograms and accurately position them, greatly reducing the need for manpower.

(4) Efficient Battery Drive, Long-Term Continuous Operation

Electric warp-beam trolleys equipped with large-capacity lithium batteries can support long-term operation and are suitable for high-intensity workshop working environments. They reduce the frequency of charging and further improve work efficiency.

Safety Design of Electric Warp Beam Trolley

(1) Automatic Braking System to Prevent Slipping

Electric warp beam trolleys are usually equipped with automatic braking and parking systems, which can automatically lock the wheels when the equipment stops running to prevent slipping and ensure safety.

(2) Intelligent Anti-Collision System to Avoid Accidental Collisions

Some high-end models are equipped with radar or infrared sensing systems, which automatically slow down or even brake when approaching obstacles to reduce collision accidents.

(3) Anti-Rollover Structure to Ensure Stability

The chassis structure of the equipment has been optimized, with a more stable center of gravity. Even when carrying overweight warp beams, it can ensure that the equipment will not roll over, ensuring the safety of personnel and equipment.

(4) Emergency Stop Button to Provide Additional Protection

All electric warp beam trolleys are equipped with an emergency stop button, which allows the operator to quickly stop the equipment in case of emergencies and reduce the risk of accidents.

Future Development Trend

With the intelligent upgrading of the textile industry, the future electric warp beam trolley will develop in a smarter, more efficient, and more environmentally friendly direction. for example:

Automatic navigation system: AGV (automatic guided vehicle) technology will be introduced to enable the warp beam trolley to navigate autonomously and improve the level of automation.

Remote monitoring and data management: The intelligent electric warp beam trolley will support remote monitoring, and managers can check the operating status of the equipment at any time to improve management efficiency.

Energy-saving and environmentally friendly design: Use more energy-saving motors and low-energy batteries to improve the environmental performance of the equipment.

Conclusion

In modern textile workshops, the Electric Warp Beam Trolley not only improves handling efficiency but also greatly improves safety and reduces labor costs. Its efficient electric drive, intelligent steering, precise lifting,and multiple safety features make it an indispensable handling tool in textile workshops.

For textile companies, choosing a suitable electric warp beam trolley can optimize the production process and improve overall competitiveness, making production smoother, more efficient, and safer.