In denim production, the heavy fabric structure, complex weaves, and diverse dyeing and washing processes present significant challenges for traditional cloth inspection. As order volumes grow and quality standards rise, more denim mills are turning to intelligent fabric inspection systems to enhance detection stability and production efficiency.

But with so many AI fabric inspection solutions on the market, how do you choose the one that truly fits denim?

Why Denim Demands More from Fabric Inspection

Compared to standard woven fabrics, denim presents unique difficulties during the inspection process:

- High fabric weight with prominent surface textures.

- Complex twill weaves that can interfere with defect recognition.

- Subtle defects: Issues like shading, oil spots, and broken warps are harder to spot.

- Consistency requirements: Multiple batches and finishing processes demand higher uniformity.

This is why many traditional cloth inspection methods lead to missed detections or false alarms when applied to denim.

Key Factors When Choosing an Intelligent Fabric Inspection System

AI Algorithms Adapted to Denim Texture

For denim, an AI fabric inspection system must be capable of recognizing twill structures and dark surfaces. A mature AI model should distinguish between normal weave patterns and actual defects, preventing the system from misidentifying texture as a flaw.

Detection Capabilities for Oil Spots, Shading, and Holes

Oil stains and color shading are high-frequency issues in denim production. A premium intelligent fabric inspection system should offer:

- Detection of low-contrast oil spots.

- Stable identification of minor anomalies on dark fabrics.

- Precise localization of structural defects like holes.

Inspection Speed Matching Production Rhythms

Denim production emphasizes continuity; if the inspection speed is too slow, it becomes a bottleneck. When selecting an AI cloth inspection machine, focus on its stable operating speed in real-world conditions, not just theoretical specs.

Industrial-grade systems typically support stable inspection speeds of 40-60 m/min, which better meets the high-efficiency needs of denim mills.

System Stability and Industrial-Grade Design

The heavy nature of denim requires robust equipment structure and operational stability. A reliable system should feature:

- Stable fabric transport and tension control.

- The durability to handle multi-shift, long-term operation.

- Industrial-grade hardware to minimize maintenance frequency.

Data Output and Quality Management

Modern denim factories focus on traceable quality management. AI fabric inspection should do more than just "find flaws"; it should:

- Automatically generate inspection reports.

- Record defect types and their distribution.

- Provide data support for process optimization and customer communication.

Why Are More Denim Mills Choosing AI Fabric Inspection?

Compared to traditional cloth inspection, AI systems offer value beyond just speed:

- Improved Consistency: Maintains quality standards across different batches.

- Reduced Labor Dependency: Decreases reliance on highly skilled manual inspectors.

- Smart Manufacturing: Supports the transition to automation and Industry 4.0.

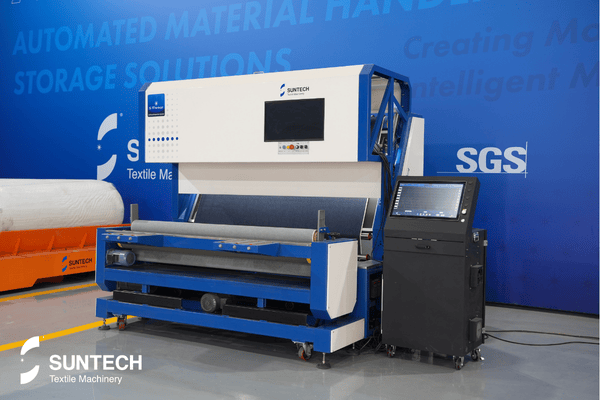

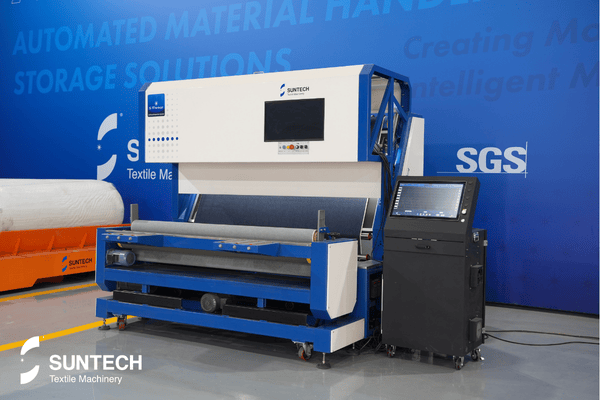

Performance of SUNTECH’s Intelligent Solutions in Denim Applications

SUNTECH’s Automatic Camera Inspection Machine was designed with heavy fabrics like denim in mind:

- Supports high-speed, stable automated inspection.

- AI algorithms tailored for complex textures and dark fabrics.

- Seamlessly integrates into automated production and quality management workflows.

Conclusion

Choosing the right intelligent fabric inspection system for denim isn't about the longest list of specs—it’s about how well the system adapts to denim’s unique structure, production pace, and quality goals.

Stable, intelligent, and continuously optimized AI fabric inspection is becoming a core competitive advantage for modern denim factories.