In traditional cloth inspection processes, identifying defects such as broken ends, oil stains, and holes relies heavily on the experience and focus of the inspector. However, as production speeds increase and fabric structures become more complex, manual methods struggle to maintain stability and consistency.

AI fabric inspection utilizes computer vision and deep learning technology to achieve automated, continuous, and standardized identification of surface defects.

1. High-Resolution Image Acquisition: Restoring Real Surface Conditions

The first step in AI inspection is the high-speed, high-definition image acquisition of the moving fabric. Industrial cameras continuously capture fabric details at high speeds, ensuring that broken ends, small oil stains, or minute holes are not overlooked.

Compared to traditional manual visual inspection, this stage is unaffected by eye fatigue or subjective judgment, providing a stable data foundation for subsequent identification.

2. How AI Algorithms Identify Broken Ends

Broken ends typically manifest as a disruption in the continuity of the fabric structure or abnormal changes in texture regularity. In an AI fabric inspection system, the algorithm models fabric texture features by learning from a vast number of normal and abnormal samples:

Automatically identifies abnormal interruptions in warp and weft directions.

Quickly locates broken end areas by comparing them against the normal fabric structure.

Maintains stable identification even in high-density or complex weave structures.

This allows AI to be more effective than humans at detecting "easily overlooked" structural defects during continuous production.

3. How AI Identifies Oil Stains and Color Shading

Defects such as oil stains and color shading usually appear as localized abnormalities in color, reflection, or brightness. The AI cloth inspection system performs multi-dimensional image feature analysis to:

Identify color distributions inconsistent with the background fabric.

Analyze regions with abnormal brightness and contrast.

Distinguish between intentional process textures and unintended contamination.

Through continuous AI deep learning, the system gains stronger adaptability to oil stain appearances across different fabrics and dyeing processes.

4. How AI Detects Holes

Holes are serious defects with diverse shapes, varying significantly in size and edge morphology. During the fabric inspection process, AI combines shape recognition with regional analysis:

Identifies areas where surface continuity is missing.

Analyzes the difference between the hole edges and the background texture.

Automatically determines the size and severity level of the hole.

Compared to manual inspection, AI maintains stable detection even at high operating speeds, minimizing the risk of missed inspections.

5. From Identification to Data: The Value of AI Cloth Inspection Goes Beyond "Seeing"

Unlike traditional inspection, an AI fabric inspection machine not only identifies defects but also transforms results into actionable data:

Automatically records defect types, locations, and distributions.

Generates traceable quality inspection reports.

Provides a basis for subsequent process optimization and quality analysis.

This elevates cloth inspection from "result judgment" to "process management."

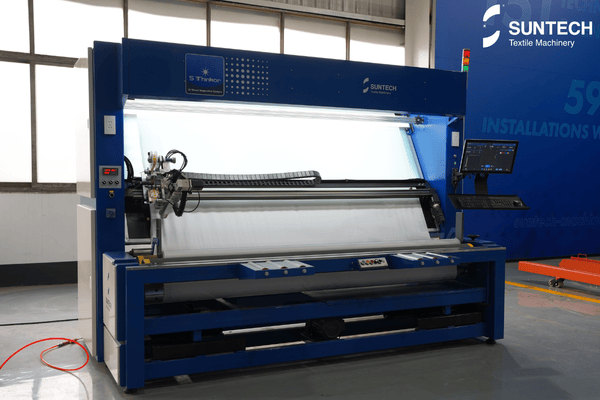

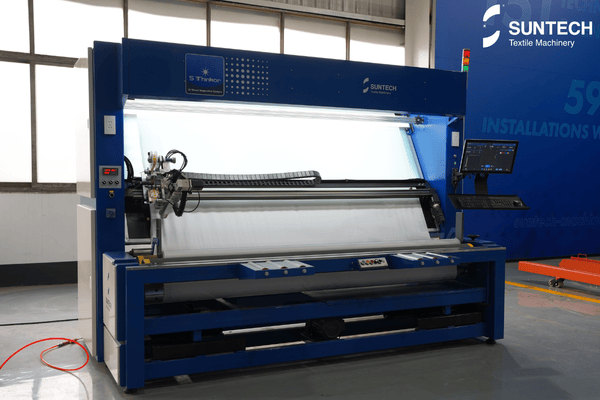

6. Practical Application of Industrial-Grade AI Fabric Inspection

In real-world production environments, AI inspection systems must balance stability, speed, and adaptability. The SUNTECH Automatic Camera Inspection Machine is developed specifically for industrial application requirements, supporting continuous automated inspection and adapting to various fabrics and production scenarios.

Conclusion

AI identifies surface defects like broken ends, oil stains, and holes through image acquisition, feature recognition, and deep learning models. Compared to manual methods, AI fabric inspection offers significant advantages in stability, efficiency, and digitalization, becoming a core technology in modern cloth inspection.