As the textile industry faces increasing demands for quality consistency, delivery stability, and labor cost control, traditional manual inspection—which relies heavily on human experience—is struggling to meet the needs of modern production. In this context, AI fabric inspection is rapidly becoming an essential upgrade for weaving mills, dyeing and finishing plants, and fabric suppliers.

But how exactly is AI applied in fabric inspection? And what practical changes can it bring to a factory?

The Shift from Manual to AI Fabric Inspection

Traditional cloth inspection primarily relies on manual visual checks, which present several common challenges:

- High Miss Rates: Fatigue from long shifts leads to human error.

- Subjective Standards: Consistency varies between different employees.

- Data Gaps: It is difficult to record, trace, or analyze comprehensive defect data.

- Rising Costs: Increasing labor wages and the pressure of night/multi-shift rotations.

In contrast, an AI fabric inspection machine leverages computer vision and deep learning technologies to transform the process from "experience-driven" to "data-driven."

How Does AI Work in Fabric Inspection?

In practice, an AI inspection system is not just a simple "camera for taking pictures." It is a complete workflow powered by several collaborative technologies:

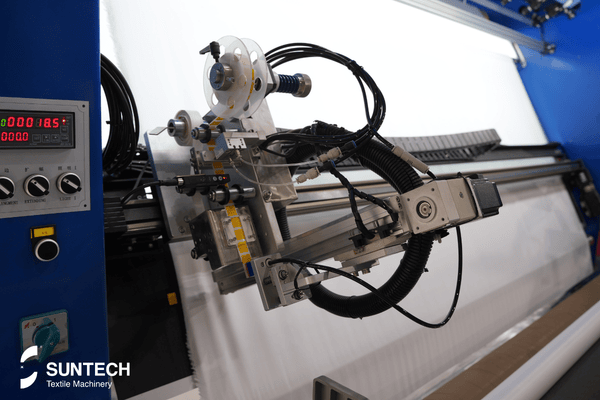

1. High-Speed Image Acquisition

2. Industrial-grade cameras continuously capture high-definition images as the fabric moves, covering the entire width and all critical areas to provide a stable data foundation for analysis.

3. AI Defect Recognition and Classification

4. Using deep learning algorithms, the system automatically identifies common fabric defects—such as oil stains, holes, color shading, weft skew, and streaks—while continuously learning new defect types. This is the core advantage of AI fabric inspection over traditional automated methods.

5. Real-Time Judgment and Data Output

6. The AI assesses defect severity based on preset standards and generates a complete report, including the location, type, size, and distribution of defects, providing reliable data for subsequent processes.

What Practical Problems Does AI Cloth Inspection Solve?

Applying AI to fabric inspection isn't just about being "advanced"; it directly addresses key factory pain points:

- Stable Inspection Quality: Operates 24/7 without being affected by human fatigue or mood.

- Increased Efficiency: Inspection speeds can reach 3–5 times that of manual labor.

- Reduced Labor Dependency: Enables "light-out" or reduced-staffing inspection rooms.

- Data Traceability: Provides a solid basis for quality analysis, process improvement, and customer communication.

For factories focusing on export orders or high-end clients, stable and quantifiable cloth inspection capabilities often directly influence their ability to secure orders.

SUNTECH’s AI Fabric Inspection Solution

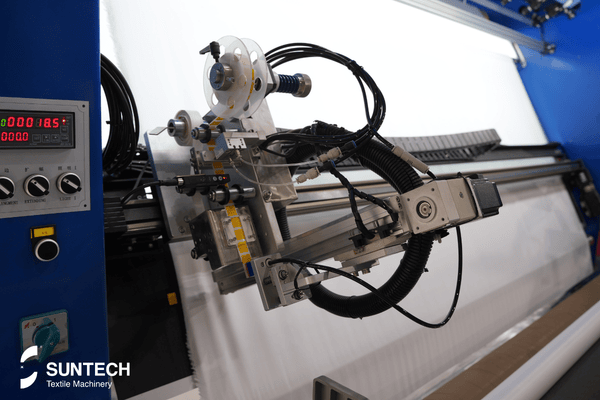

In real-world applications, system stability and algorithm maturity are critical. The SUNTECH Automatic Camera Inspection Machine is specifically designed for industrial-grade fabric inspection scenarios:

- 24/7 Continuous Operation: Supports fully automated, around-the-clock inspection.

- Massive Defect Database: Features built-in AI deep learning for continuous accuracy improvements.

- High Adaptability: Stable precision across various fabric types and working conditions.

- Seamless Integration: Can be integrated with downstream packaging and sorting systems to build a fully automated workflow.

Conclusion

AI fabric inspection is the future of the industry. As labor costs rise and customer demands for quality transparency increase, it is no longer an "optional" luxury but a foundational capability for the modern textile factory. It doesn't just change how we inspect cloth; it drives the entire quality management system toward a digital and intelligent future.