In today’s competitive garment manufacturing industry—marked by tight delivery schedules and increasingly high client standards—every factory faces the same urgent question: how to improve product quality at the source, boost production efficiency, and reduce material waste. A highly efficient and stable fabric relaxing machine, though often overlooked, can quietly bring substantial returns before the cutting stage even begins.

If you’ve experienced any of the following issues:

Garments shrink or deform after cutting and washing, triggering frequent customer complaints

Fabric wrinkles or stretches unevenly during spreading, leading to cutting inaccuracies

Sewing becomes more difficult, with frequent rework and low efficiency

Over-preparing fabric inventory leads to material waste and higher storage pressure

it likely means your factory needs a fabric relaxing machine before cutting. Though small in size, it’s the “behind-the-scenes hero” that directly impacts product yield and profit margins.

The Role of the Fabric Relaxing Machine

After weaving, dyeing, and finishing, fabrics often retain significant mechanical tension. If not released, this tension manifests in various issues during cutting—shrinkage, dimension deviation, and sewing difficulties—all of which affect final product quality.

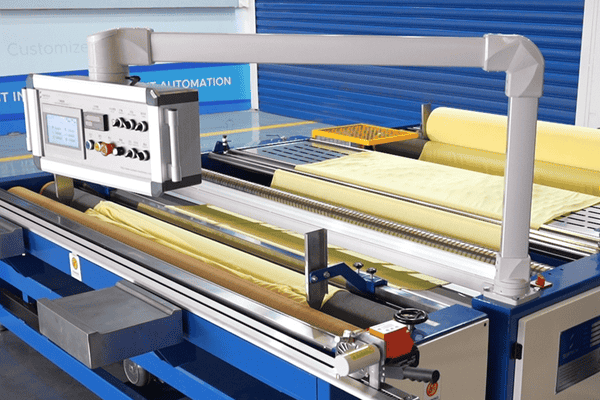

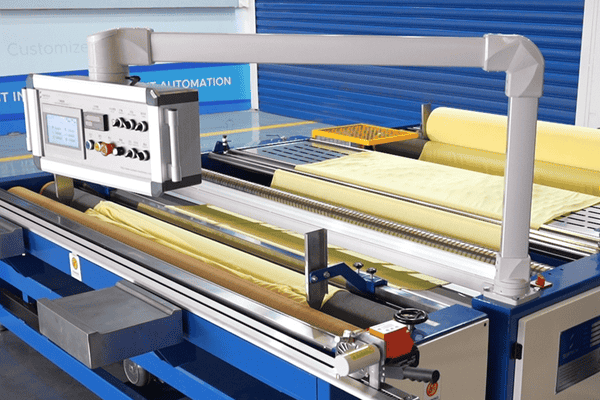

The fabric relaxing machine is designed specifically to solve this. Through a combination of tension-free laying, swinging descent, and gravity-based stacking, the machine allows fabrics to relax and recover their natural dimensions in a low-tension or tension-free state. This makes the fabric more stable and predictable for cutting and acts as a crucial bridge between raw materials and finished garments.

Tangible Economic Benefits

Reduce Shrinkage Complaints & Improve Customer Satisfaction Without fabric relaxation, materials—especially high-stretch knits and functional fabrics—often shrink noticeably after washing, with rates as high as 3%–5%. Size mismatches can lead to a surge in returns and damage brand reputation.

1.After fabric relaxing treatment, pre-shrinkage is done before cutting, keeping shrinkage below 1%, greatly reducing end-customer complaints.

✅ More stable garment sizes

✅ Consistent quality control

✅ Lower return rates, better brand reviews

Improve Cutting Precision & Reduce Waste Tensioned fabrics tend to shift, bounce, or bunch up during spreading, leading to inaccurate cutting. This can result in slower sewing or even costly re-cutting.

2.Relaxed fabrics are more stable in elasticity and thickness, making them lay flatter. This significantly reduces manual errors and improves the precision of automatic cutters or templates.

✅ 1%–2% average reduction in cutting waste

✅ Better fabric utilization per roll

✅ Significant monthly raw material savings

Boost Sewing Efficiency & Reduce Rework Tensioned fabrics often cause issues during sewing: misalignment, puckering, or uneven garments. These affect appearance and production speed.

3.Relaxed fabrics are softer and more pliable, easier for sewing machines and operators to handle. This raises overall productivity and reduces rework.

✅ 10%–15% improvement in sewing efficiency

✅ Higher pass rates for finished products

✅ Overall production line efficiency boost

Reduce Fabric Overstock & Inventory Pressure To guard against shrinkage, many factories prepare 10%–15% more fabric than needed—raising raw material costs and storage burden.

4.With predictable and controllable shrinkage after relaxation, factories can order and prepare fabric more precisely, achieving “on-demand production” and easing cash flow pressure.

✅ Lower average procurement costs

✅ Freed-up storage space

✅ More flexible warehouse management

Meet High-End Brand & Export Standards More global brands and overseas clients demand garment stability, consistent hand feel, and fabric thickness. For example, EU and U.S. buyers often require shrinkage rates below 1%.

5.Fabric relaxing machines help control these parameters at the source, supporting ISO-level quality compliance, and making it easier to win big-brand or export orders.

✅ Easier to pass client inspections

✅ Stronger brand negotiation power

✅ Access to higher-end markets

Low Cost, Fast ROI

Compared to other large textile machinery, a fabric relaxing machine requires relatively low investment. Yet its return is immediate—through higher efficiency, fewer returns, and less rework.

Most factories see ROI within 3 to 6 months.

More importantly, the long-term value it brings in product quality and customer satisfaction goes far beyond monetary measurement.

Conclusion

Fabric relaxing lays a stable foundation for the processes that follow. It directly determines size accuracy, product quality, and manufacturing efficiency. The fabric relaxing machine is one of the smartest long-term investments a garment factory can make.

If your factory is struggling with cutting errors, frequent shrinkage complaints, or constant rework, it may be time to introduce a fabric relaxing machine—it could be the critical step you’ve been missing.