As a specialized and renowned brand in the textile machinery industry, SUNTECH Textile Machinery has garnered substantial expertise in the development, production, supply, and sales of textile machinery since 1970. Over the course of 50 years, our commitment extends beyond mere success as a company; we strive to infuse value creation into every aspect of our customer-centric approach. Our unwavering dedication drives us to channel all our resources and talent towards the continuous advancement of intelligent and automated manufacturing lines for textile machinery.

![10插图]()

Presently, our collaboration spans across 5,000 customers worldwide, with our machines being exported to over 120 countries. An impressive fleet of 17,000 machines remains steadfastly operational in various global regions. The contemporary global landscape has witnessed transformative shifts, reshaping the very fabric of human existence, encompassing domains such as lifestyle, work, healthcare, and education. Amidst these transformative waves, we have witnessed the remarkable influence and value of digitization and technology. These forces have become irrevocable drivers of innovation, compelling SUNTECH Textile Machinery to continuously embrace cutting-edge technology and integrate it into our textile machinery.

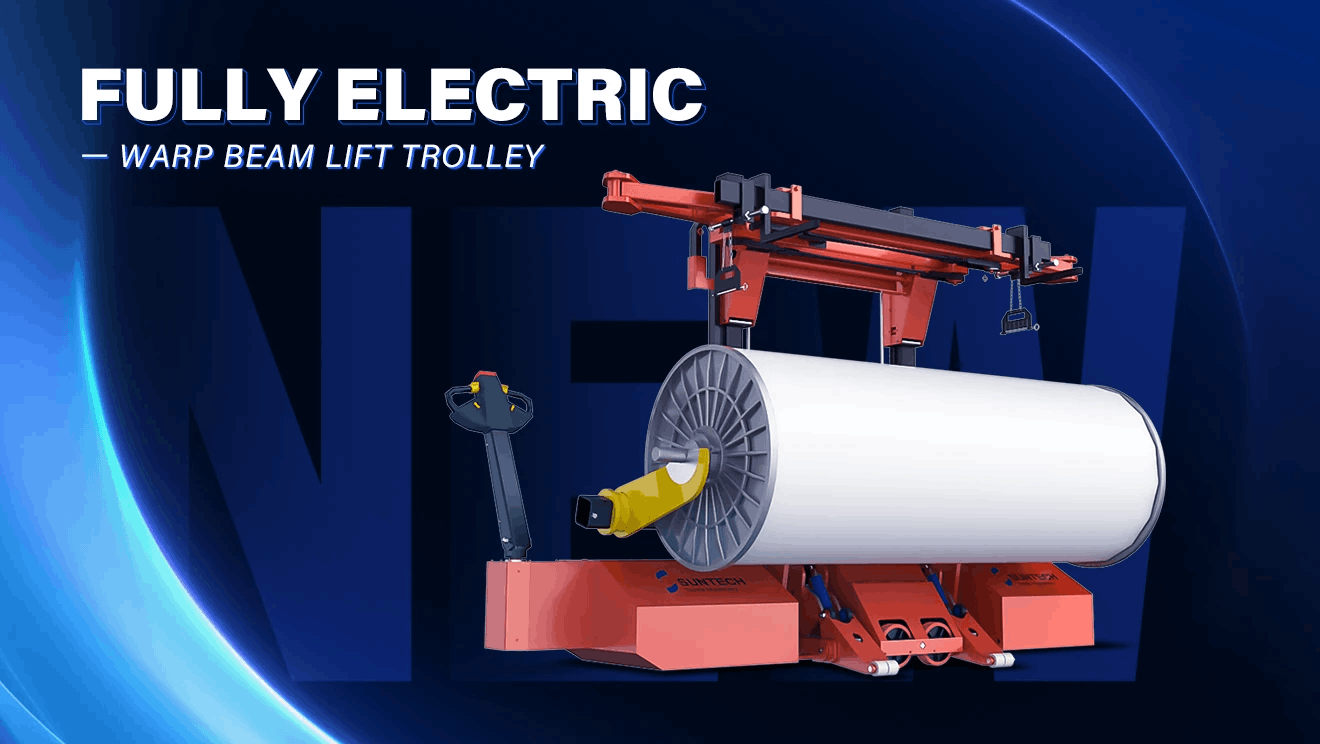

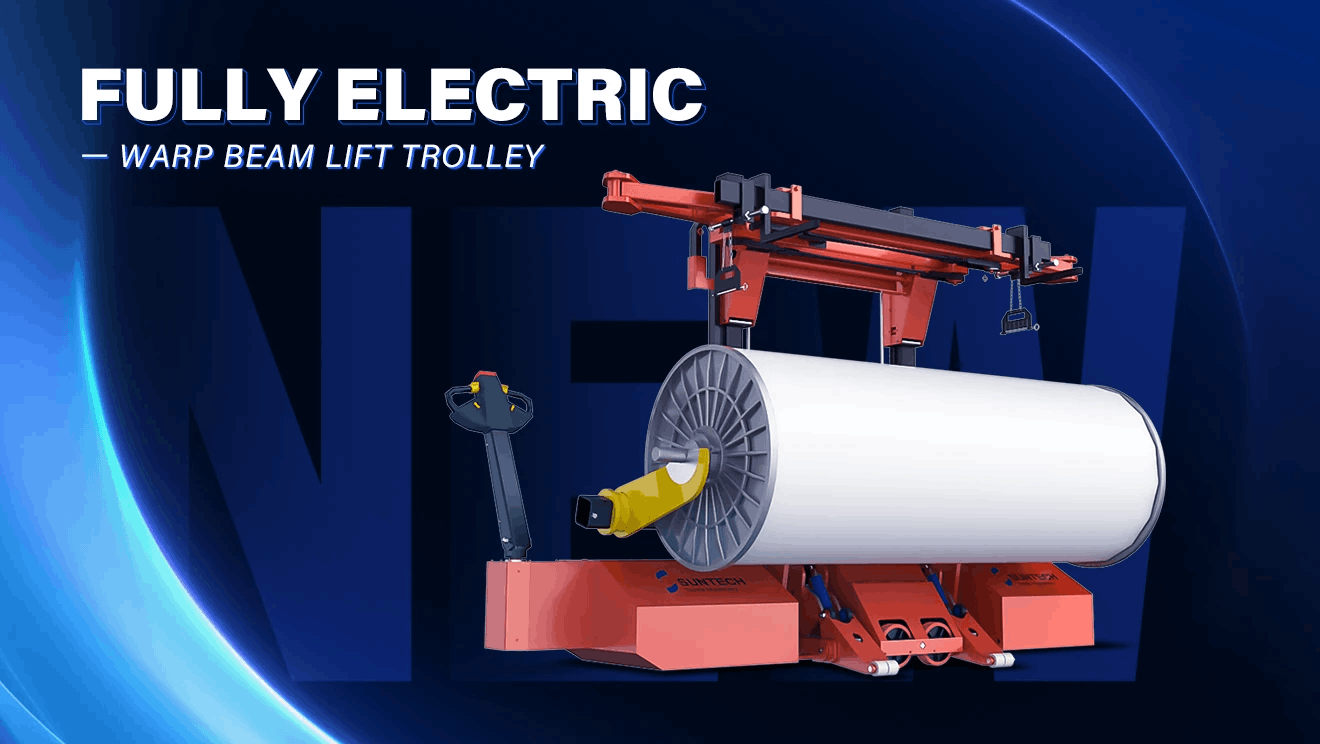

At present, we are thrilled to unveil our latest product enhancement, the ST-MBT-02I Motorized Warp Beam Lift Trolley with Harness Mounting Device. Designed specifically for the seamless transportation of bottom beams and harnesses, this cutting-edge model is seamlessly integrated into weaving machines. Placing utmost importance on customer satisfaction, we prioritize the success of our valued clientele, continuously adapting to their evolving needs and preferences. This upgraded product, compliant with stringent European standards, offers intuitive operation while significantly reducing costs for our esteemed customers, resulting in remarkable savings of up to 40%. This represents a monumental leap forward in our commitment to delivering innovative solutions.

Introducing the cutting-edge ST-MBT-02I, our newest model tailored for seamless bottom beam transportation and effortless integration into weaving machines. Designed to accommodate weave beams weighing up to 1800kg and customized beam widths, this advanced trolley boasts an additional loading capacity of 300kg specifically for the harness. Remarkably versatile, it seamlessly adapts to weaving machines with a standard working width of 170-340cm without necessitating any size modifications.

The harness is easily accommodated through the standard take-up for the harness frame, alongside contact rails and dividing rails or the comprehensive weave stop motion. We invite you to explore the functionality and features of our Motorized Warp Beam Lift Trolley.

This fully motorized trolley comprises three essential systems: the driving system, the beam lifting system, and the harness mounting system. Each system harmoniously integrates to provide a seamless and efficient user experience.

Driving System:

The motorized warp beam lift trolley effortlessly glides on two drive wheels and three supporting wheels, with travel direction conveniently controlled by the handle. Here's how the driving system operates:

For long-distance travel, simply turn the handle to the linear position, retract the beam lifting system, and activate the speed knob to set the trolley in motion.

To approach weaving beams or looms, adjust the handle to the vertical position, extend the beam lifting system, and engage the speed knob. At this point, the left and right driving wheels can be independently controlled to fine-tune the trolley's alignment with the beam/loom. Notably, the handle employs an electric steering system, reducing labor requirements for turning by a remarkable fivefold.

Beam Lifting System:

As the trolley nears the beam/loom, the operator can effortlessly adjust the hook position to load or retrieve the beam. Noteworthy features of the beam lifting system include:

The inclusion of a Side Shift Function, allowing the hook to transversely move left and right by 100mm when the trolley is stationary. This function proves exceptionally convenient, safe, and time-saving when maneuvering within limited spaces. Powered by an electric linear actuator, it offers enhanced stability and ease of maintenance compared to traditional oil cylinders.

The hook comes equipped with detachable pads designed to accommodate various beam heads, including those used in Picanol and Toyota machines.

![39插图2]()

Harness Mounting System:

With the harness mounting device, operators have full control over the upward and downward movement, as well as the stretching and contracting actions of the heald frames and droppers. Here's how the harness mounting system operates:

Both the handle and the remote control enable operators to seamlessly control the harness mounting device for loading/unloading purposes.

An electric linear actuator powers the harness mounting device, allowing for efficient adjustment. When loading work onto looms, operators can use the handle for initial positioning and then utilize the remote control from the opposite side of the loom for precise and accurate fine insertion. This process significantly enhances convenience, accuracy, and overall safety.

This fully Electric Warp Beam Lift Trolley with Harness Mounting Device embodies exceptional performance, versatile operability, and a sleek design, making it an ideal solution for your needs.

![39插图1]()

SUNTECH Textile Machinery ardently acknowledges the transformative influence of digitization and technology across various domains, ranging from healthcare and education to work environments. Consequently, we remain resolutely committed to driving innovation, perpetually at the vanguard of technological advancements, seamlessly integrating them into our textile machinery to deliver unparalleled value and future-forward solutions.