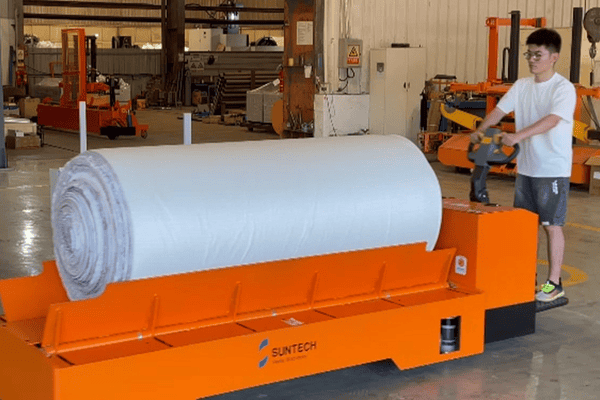

In the daily operations of textile mills, handling heavy materials such as warp beams and fabric rolls is a frequent and labor-intensive task. Traditional manual handling is not only inefficient but also poses high risks of workplace injuries and equipment damage, leading to significant hidden costs. The introduction of the electric warp beam trolley has fundamentally transformed this situation. So, how much can purchasing an electric warp beam trolley actually save for a textile factory? Let’s break it down.

Reducing Labor Costs

Manual handling typically requires multiple workers. For example, transporting a single heavy warp beam might need two to three workers cooperating.

After introducing an electric warp beam trolley:

- A single operator can complete the transport task independently, reducing dependence on multiple workers.

- Labor demand can be reduced by 40%–70%, directly lowering wage expenses.

For instance, in a medium-sized textile factory, if 10 workers were originally needed for material handling, using electric warp beam trolleys may reduce this to just 3–4 workers.

Lowering Worker Injury Compensation Costs

During warp beam handling, due to the heavy lifting and confined spaces, common accidents include:

- Lumbar spine injuries

- Fractures caused by collisions

- Injuries from dropped beams

Such incidents often lead to high medical compensation expenses, ranging from several thousand to tens of thousands of RMB, and may even result in labor disputes.

By using electric warp beam trolleys:

- Mechanized operations reduce the risk of personal injury by over 90%.

- Companies can save at least 30,000–50,000 RMB annually in injury-related costs and hidden compensation expenses.

Reducing Equipment Damage Costs

Manual handling frequently causes issues such as:

- Warp beams dropping

- Beam heads and loom parts getting damaged

Electric warp beam trolleys are equipped with soft support structures and smooth lifting systems, effectively protecting warp beams and equipment, significantly reducing:

- Equipment repair costs

- Warp beam replacement costs

- Indirect losses caused by production downtime

Statistics show that repairing a damaged loom beam head can easily cost thousands of RMB. By adopting electric warp beam trolleys, textile mills can reduce accidental equipment damage costs by at least 50,000–100,000 RMB annually.

Boosting Production Efficiency and Generating Additional Revenue

Beyond cost savings, electric warp beam trolleys significantly enhance handling speed:

- Transport efficiency increases by 2–3 times

- Material flow speeds up within the workshop

- Machine uptime improves, leading to higher output

If a factory can increase finished fabric production by even 2%–3% daily, based on an annual output value of 20 million RMB, it could generate an additional 400,000–600,000 RMB per year—directly contributing to profit growth.

Overall Return on Investment (ROI) Analysis

The cost of purchasing a high-quality electric warp beam trolley typically ranges from 50,000–150,000 RMB.

However, considering the benefits from saving labor, reducing injuries, minimizing equipment damage, and boosting productivity, most factories can recoup their investment within 6–12 months. Thereafter, the annual net savings can exceed 300,000 RMB, delivering an exceptionally high return on investment.

Long-term Strategic Savings

Beyond direct economic benefits, electric warp beam trolleys also offer:

- Enhanced corporate image, attracting more customer orders

- Improved workshop working conditions, meeting occupational health standards

- Reduced hiring pressure, adapting to labor shortages

- A strong foundation for smart and automated manufacturing upgrades

These "soft savings" will significantly strengthen a textile factory’s competitiveness over the medium and long term.

Conclusion

Purchasing an electric warp beam trolley is not just about saving money—it's about making money.

Through a one-time investment, textile mills can dramatically cut operating costs, enhance production efficiency, and sharpen their market edge. In an era of rising labor costs and accelerated smart manufacturing development, electric warp beam trolleys are undoubtedly the best choice for textile companies aiming to reduce costs, boost efficiency, and move towards intelligent workshops.