Have you ever wondered how textiles were made before the Industrial Revolution? While the manual labor and skill needed to create beautiful textiles was immense, the ingenuity of an ancient Chinese machine may have simplified things a little. Find out more in this article about the ancient texile weaving machine in China, and discover how it revolutionized cloth weaving.

Introduction of Ancient Textile Weaving Machine in China

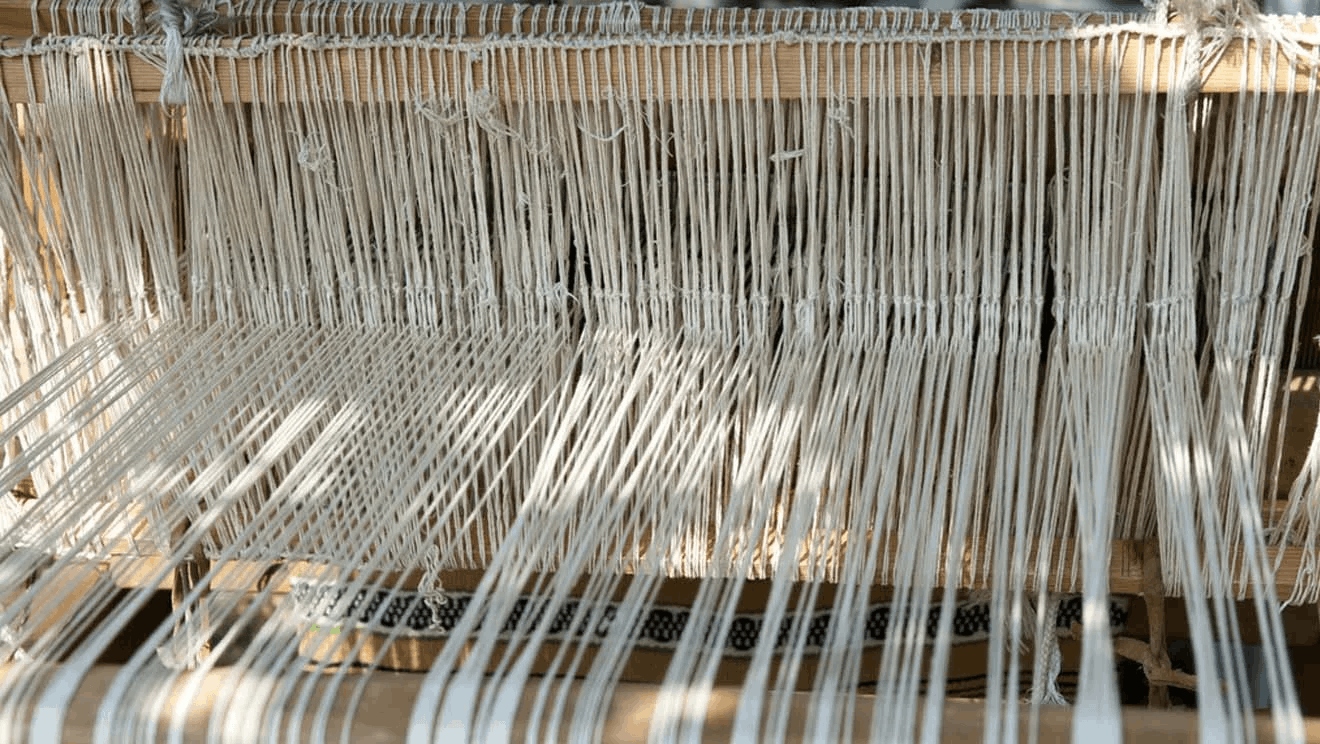

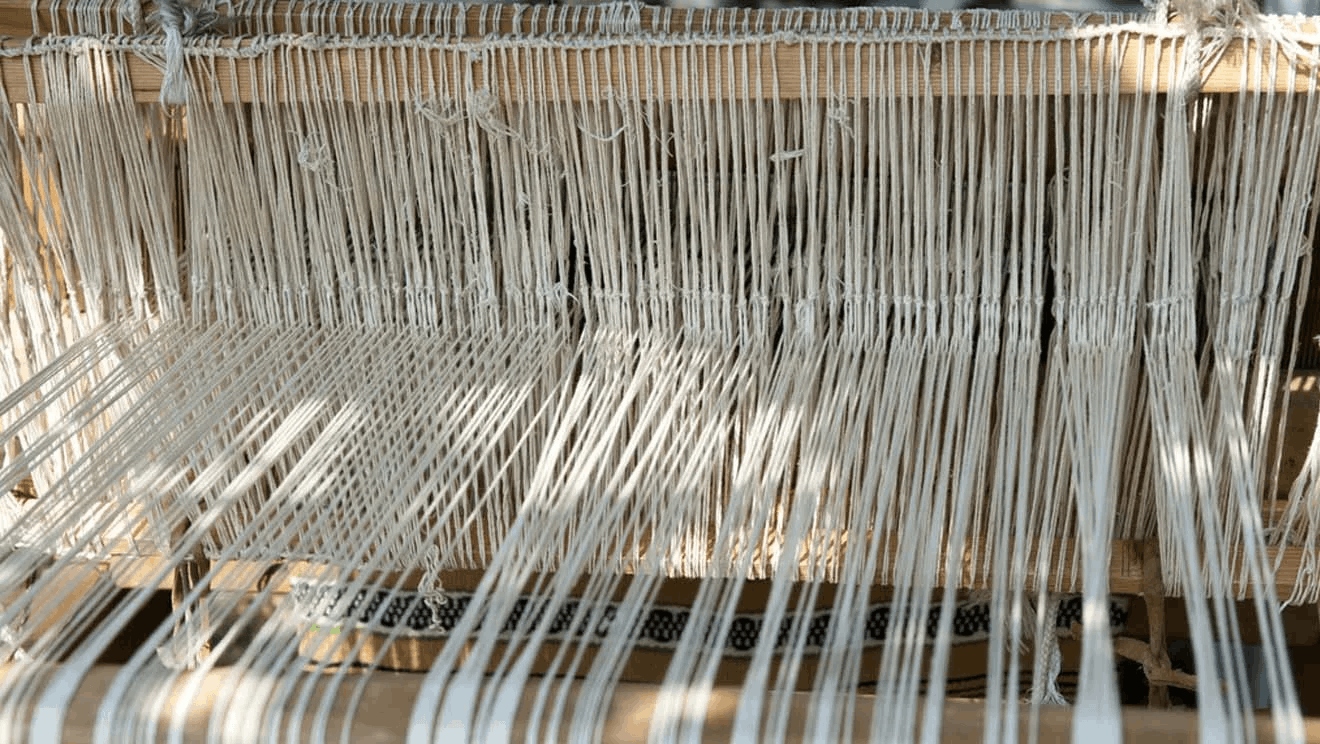

In ancient China, the first textile weaving machine was introduced and it revolutionized the fabric industry, which was called the warp-weighted loom, it was a large, vertical loom that had weights attached to the bottom of the warp threads. The warp threads were stretched taut horizontally between 2 beams at the top of the loom, and the weaver sat on a platform that could be raised or lowered depending on where they needed to reach in order to weave the cloth.

The warp-weighted loom allowed for much longer lengths of fabric to be woven at one time, which increased productivity and efficiency. This new weaving machine quickly became popular and was widely used throughout China. It is still used today in some parts of the world, particularly in areas where there is no electricity or running water.

History of the Technology

The ancient Chinese people were skilled in the art of weaving and their textile products were in high demand by other cultures. In order to meet the demand, the Chinese developed a machine that could speed up the process of weaving. This machine was called the pingtung machine and it was used to produce textiles that were of a high quality and had intricate designs. The machine was operated by two women who worked together to operate it. The first woman would sit on the lower level of the machine and use her feet to power the loom, while the second woman sat on the upper level and used her hands to guide the shuttle. The pingtung machine was very efficient and could produce up to eight bolts of cloth per day.

Types of Weaving Machines

There are 2 types of weaving machines: the hand loom and the power loom. The hand loom is a simple machine that is powered by the weaver's hands. The power loom is a more complex machine that is powered by a motor.

The hand loom is the simplest type of weaving machine. It consists of a frame, a shuttle, and a reed. The weaver sits in front of the loom and uses her hands to operate the shuttle, which throws the thread across the warp threads. The reedbeatsthe threads into place as the weft is woven through them.

The power loom is a more complex machine that mechanizes the process of weaving. It consists of a frame, a set of heddles, a harness, a shuttle box, and a take-up roller. The motor powers the heddles, which raise and lower the warp threads. The shuttle box holds shuttles that throw the weft threads across the warp threads. The take-up roller winds upthe finished fabric as it is woven.

![weaving machine]()

Benefits of Textile Weaving Machines in China

Textile weaving machines have been used in China for centuries, and their benefits are still being enjoyed today. These machines allow for a greater degree of control over the fabric than hand-weaving, resulting in fabrics with a more consistent finish. In addition, textile weaving machines are much faster than hand-weaving, meaning that more fabric can be produced in a shorter time frame.

The benefits of textile weaving machines are not only limited to the finished product. The process of operating a machine is much simpler than hand-weaving, meaning that less training is required for workers. This results in fewer errors and greater efficiency overall.

Textile weaving machines have had a profound impact on the Chinese textile industry, and continue to do so today. Their benefits are many and varied, making them an essential part of the industry.

Challenges Faced by Ancient Textile Weavers in China

Weaving is one of the oldest textile arts, and China has a long and rich history of textile production. However, ancient Chinese weavers faced many challenges, from the scarcity of suitable materials to the difficulty of creating complex patterns.

One of the biggest challenges faced by ancient Chinese weavers was the scarcity of suitable materials. While linen and hemp were relatively easy to come by, silk was much rarer and more expensive. As a result, only the wealthy could afford to purchase silk fabrics.

Another challenge faced by ancient Chinese weavers was the difficulty of creating complex patterns. Unlike modern looms, which can be programmed to create any desired pattern, ancient looms were limited in their capabilities. Weavers had to carefully plan out each thread's path in order to create even simple designs, let alone elaborate ones.

Despite these challenges, ancient Chinese weavers were able to produce some of the most beautiful and intricate fabrics in human history. Their skill and artistry is still admired today.

Recent Advances in Textile Weaving Technology

Today, the textile weaving industry in China is booming. New advances in technology have made it possible to produce finer and more intricate fabrics than ever before. The ancient craft of textile weaving is now being combined with modern innovations to create some of the most beautiful and durable fabrics in the world.

One of the latest advances in textile weaving technology is the use of air-jet looms. These looms are able to weave fabrics that are much lighter and softer than those woven with traditional shuttle looms. Air-jet looms also have the ability to produce a wide variety of patterns and designs, making them very popular with designers and fashion houses.

Another new development in textile weaving technology is the use of laser-cut templates. These templates allow for much more precise cuts and placement of fabric patterns. This newer method results in less waste and fewer irregularities in the final product.

The combination of these new technologies with traditional textile weaving techniques results in fabrics that are both beautiful and strong. The future of textile weaving looks very bright, as more and more designers are discovering the many possibilities that this ancient craft has to offer.

Enduring Legacy of Traditional Textile Weaving in China

Though the industrial revolution in China began in earnest during the late 1970s, the country has a long and storied history of textile production-one that continues to influence modern weavers. Traditional Chinese textile weaving can be traced back to at least the Warring States period (475-221 BC), when silk was first introduced to China. For centuries, silk remained the preeminent fabric used in textile production, prized for its high quality and luxurious feel.

During the Tang Dynasty (618-907 AD), Chinese weavers began experimenting with different weave structures and patterns, creating some of the first brocade fabrics. These new techniques spread quickly throughout Asia, and Tang-style brocades became hugely popular in Japan and Korea.

Even as other fabrics like cotton and linen started to gain popularity in China during the Song Dynasty (960-1279 AD), silk continued to be an important part of the textile industry. By this time, Chinese weavers had perfected a number of complicated weave structures, including tapestry and damask. They also developed a variety of bold new pattern designs, which were often inspired by nature or traditional calligraphy.

Over the centuries, traditional Chinese textile weaving has evolved to keep pace with changing fashion trends. But even today, many modern weavers continue to draw inspiration from ancient techniques and designs. As a result, Chinese textiles still have a distinctly unique look and feel-a legacy of their rich history.

Conclusion

Ancient textile weaving machines have opened the door to a wealth of knowledge about Chinese culture and its development. Not only do these artifacts reveal an incredible amount of craftsmanship, but they also tell us about the technological advances made during this time period. From traditional hand-weaving techniques to automatic mechanized production, the ancient textile weaving machine has allowed us to gain insight into China's long and rich history.